- Monday 8:00 am - 5:30 pm

- Tuesday 8:00 am - 5:30 pm

- Wednesday 8:00 am - 5:30 pm

- Thursday 8:00 am - 5:30 pm

- Friday 8:00 am - 5:30 pm

- Saturday 8:00 am - 3:00 pm

- Sunday Closed

Krone Comprima

- The all-rounder for any type of crops

- Select from 3 different press connector systems

- Fixed chamber was a convincingly simple design

- Semi-variable for maximum flexibility

- Fully variable for baling all bale sizes

- Also available as a combination bale wrapper

- NovoGrip slat and belt conveyor, the turning and compaction system for all crops

- Camless EasyFlow pick-up with w-lined tines

- Available with feed rotor or cutting system (17 or 26 blades)

- High throughputs from a massive cut-and-feed rotor

- Available with net wrap or peripheral film wrap system

- Easy and fast servicing

The EasyFlow pick-up pivots sideways and is known as the pick-up that clears the field effectively even in the most difficult conditions and at high work rates. More than that, its rugged build with very few moving parts gives an exceptionally dependable performance. |

The EasyFlow pick-up offers a 2.15 m work width (DIN 11220) for ultimate work rates. It gathers wide swaths efficiently and feeds the material in an extremely consistent flow to the feed rotor. Thanks to the generous width it is not necessary to travel through very tight turns while the machine is baling. More than that, the pivoting and spring-loaded EasyFlow provides perfect ground contouring even in very rough terrain. |

KRONE has good reasons to opt against cam track control for the EasyFlow pick-up tines. Instead of using many moving parts that are prone to wear, KRONE prefers special strippers that ensure the angle and length of the tines is always correct. |

The crop press roller unit supports the action of the pick-up. It scans the height of the swath and prepares it so that the pick-up can catch it completely. Its height is adjusted easily to adapt to the current crop, the swath volume and ground speed. |

The feed rotor and the cutting rotor of the XCut cutting unit are characterized by high throughput, smooth running and high reliability. Furthermore, XCut stands for excellent cutting quality. All Comprima balers have a drop floor as standard specification.

|

Its 53 cm diameter makes the KRONE feed rotor with tines in two chevron-style rows a powerful and reliable unit. It furthermore convinces by an extremely even supply of crops to the bale chamber. |

Featuring three rows of tines and a massive 53 cm diameter, the powerful XCut rotor has the capacity to provide consistent crop flows and precision cuts while spreading the material across the full width of the feed chamber, which is essential for forming firm edges. |

The double tines pull the crops consistently through the blades. The gap between the tines and the blades is extremely small so that not a single stem will pass the blades without cutting. This force-cut is precise and requires little force. |

The blades are protected from damage by spring locks. In case of contact with a foreign object, each blade individually ducks down and automatically returns to its initial position later on. a system that results in dependable and high-quality cuts. |

|

|

The manual control is a long lever that takes little effort to operate. Retracting half the number of blades doubles the length of cut and retracting all blades terminates all cutting. |

The optional hydraulic blade group control system is operated from the tractor seat, hence saving valuable time. |

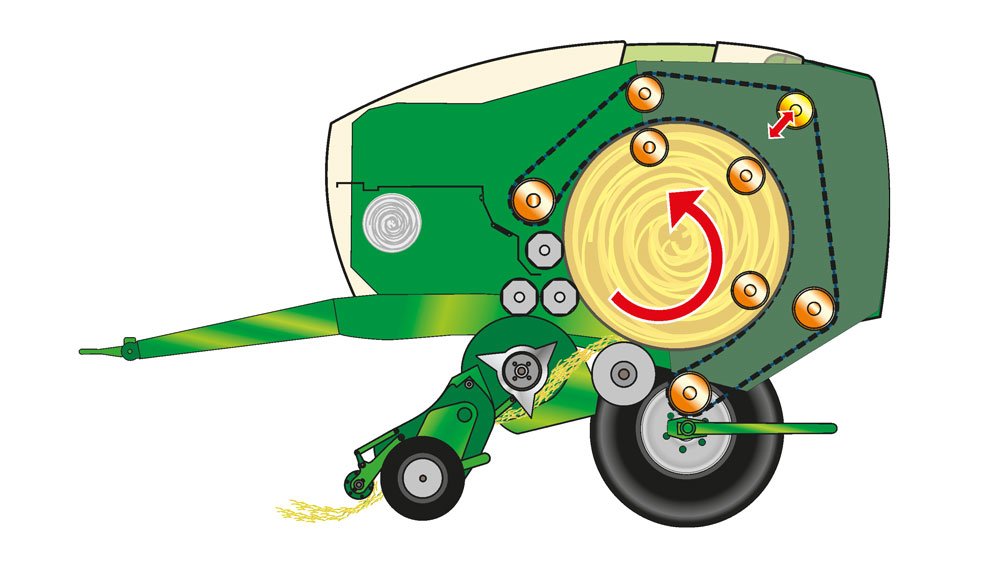

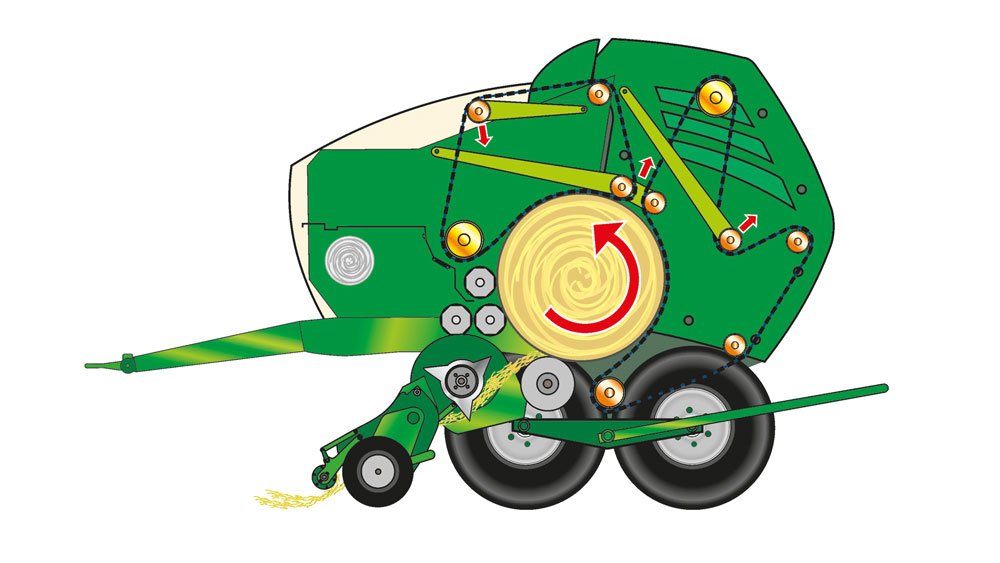

The NovoGrip is an endless slat conveyor that is made up of rubber fabric belts that turn the crops into high-density and well-shaped bales. NovoGrip offers ultimate strength and longevity and forms perfect bales from the heaviest silage. |

Thanks its special design, the NovoGrip belt-and-slat elevator suits all types of crops – straw and hay, wilted material and wet silage, performing reliably in all these conditions and treating the crop gently as the slats mesh with the bale for maximum densities and effective bale roll. |

The robust and endless rubber fabric belts with metal slats achieve unsurpassed baling densities. The system relies on an extremely high tension of the belts that effectively transfers the drive power to the bale. The slat holders mount well protected between the rubber lugs and are bolted in bushes for great durability. |

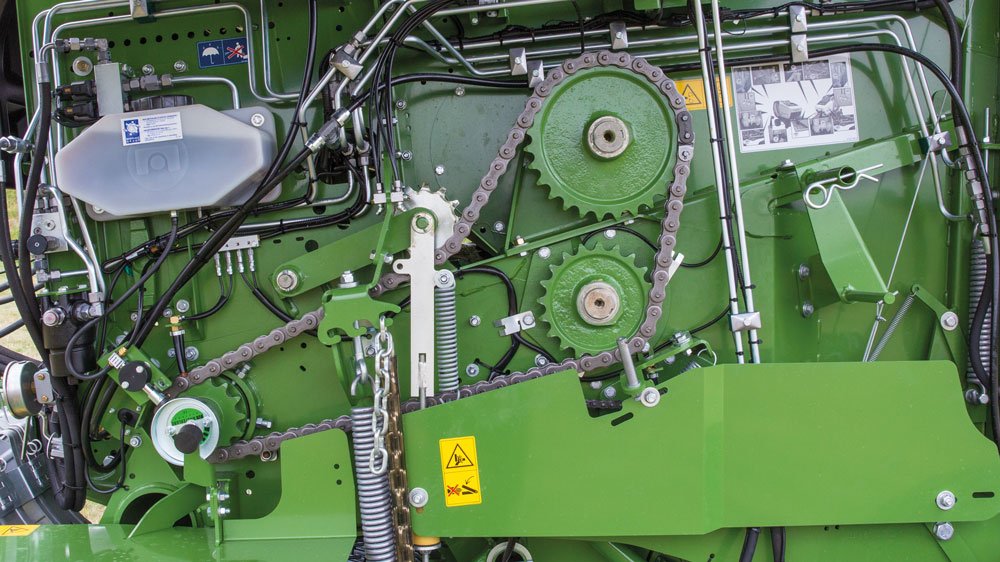

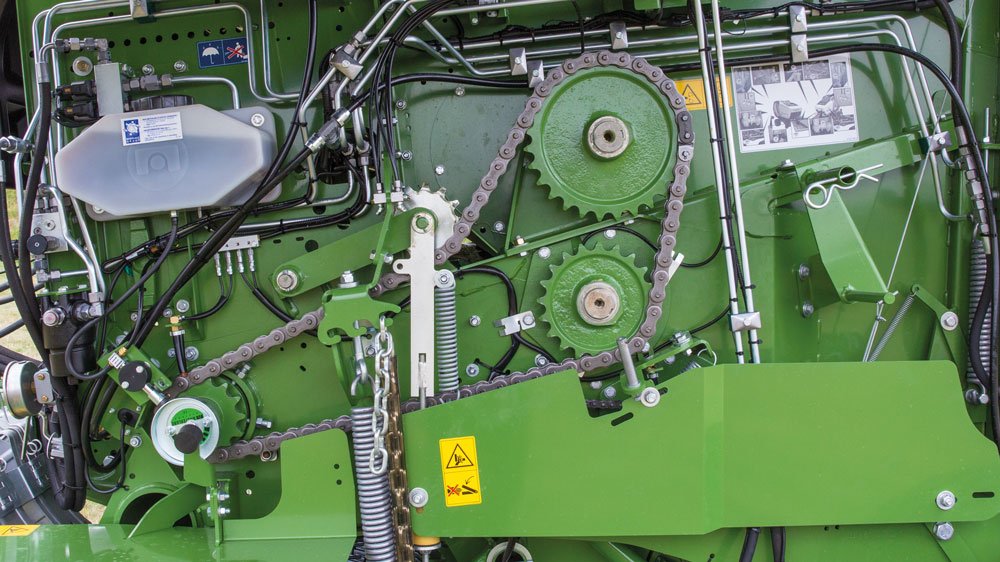

The sturdy drive chains withstand all loads. Spring-loaded chain tensioners reduce service and maintenance and extend the lifetime of the chains. |

The KRONE fixed-chamber round balers Comprima F 125 and F 125 XC convince with their simple, clear-cut and robust design, high stability, extra operator comfort and ease of maintenance. |

Comprima F 125 and F 125 XC produce fixed 1.25 m diameter bales. These versatile machines go into silage, hay and straw and stand out for exceptionally light pulling, unmatched throughputs and impressive densities. |

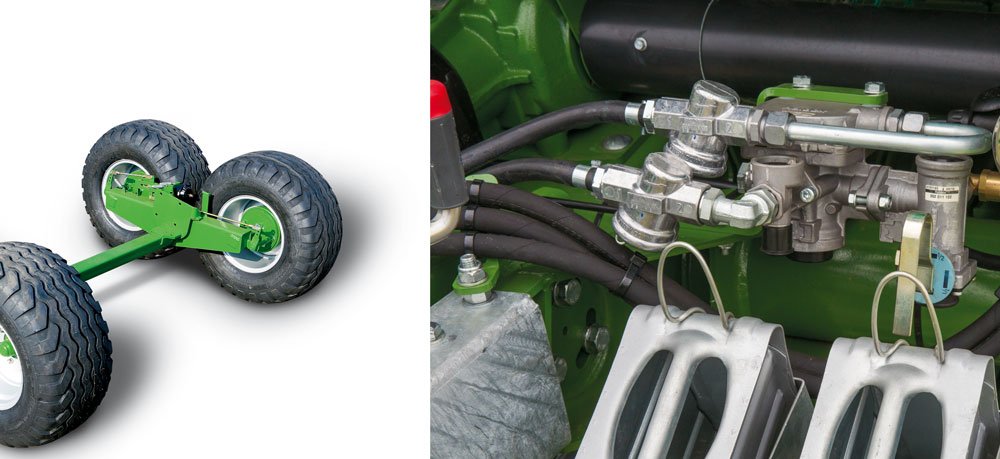

The Comprima F 125 offers optimum attachments for all conditions. Users can choose a feed rotor or cutting rotor with 17 or 26 blades, a single or tandem axle and between various control units. |

Comprima F 125 produces fixed 1.25 m diameter bales. This versatile machine goes into silage, hay and straw and stands out for exceptionally light pulling, unmatched throughputs and impressive densities. |

When first filled, the bale chamber has a slightly "angular" shape. The resulting fulling effect promotes intensive bale compaction already during this phase. As the bale chamber gets more and more full, the track of the slat and belt conveyor changes to "circular"; the bale reaches it final diameter and the set baling density. |

The KRONE Comprima F 155 (XC) and CF 155 XC are fixed-chamber round balers with semi-variable bale chamber. They bale highly compacted, dimensionally stable bales of 6 different diameters. This technology is unique on the market. They are also very cost-effective and exceptionally easy to operate and service – thanks to their uncluttered build and design. With their sturdy frame, the balers are also extremely robust and versatile. Whether silage, hay or straw – the all-round talent transforms all types of crops into bales of a consistently high quality. |

The Comprima F 155 model produces 1.25-1.50 m diameter bales. Operators simply set the required diameter in 5 cm increments on an easy-to-use system. Thus, the machine combines many advantages of fixed and variable chamber balers. They are also very cost-effective and exceptionally easy to operate and service – thanks to their uncluttered build and design. It can unload bales of different diameters and compacts from the outside to the inside; with larger bale diameters, it leaves only a very small soft core. Thus, it achieves high bale weights. |

The combination baler and wrapper Comprima CF 155 XC has all the features of the round baler plus a powerful double wrapper. The wrapping table forms a deep cradle and has large guide rollers on the sides to ensure the bale is effectively rolled during the wrapping process even when the conditions are more than difficult. The table can also be used for depositing the bales in pairs. The tandem axle is a standard specification on the Comprima CF. |

The Comprima F and CF 155 operate with a semi-variable bale chamber. They produce 1.25-1.50 m diameter bales of great densities and tidy shapes. The diameter is changed in 5 cm increments. Thanks to their simple and uncluttered build, these balers are particularly easy to service. So less time is spent on attending to the machine, and productivity increases. The bale diameter is set by refitting two pins. The general bale density is also adjustable. |

Once the bale is wrapped in the net, the tailgate of the baler opens. The bale lifter deposits the bale on the wrapping table. As the baler resumes baling, the wrapper starts the wrapping process. |

Three components are key to this bale chamber: the tensioning rocker, the spring support and the tensioning kinematics. During baling, the top tensioning rocker is pulled down as the bale chamber is filled, making room for the crop inside the bale chamber. Simply insert a bolt for easy limiting the path of the tensioning rocker and thus setting the bale diameter. The spring support combined with the tensioning kinematics provide for optimum baling density in the core as well as in the outer layers of the round bale. |

Uncompromising stability for great flexibility and continuous use under tough conditions are the distinguishing features of the KRONE Comprima V and CV. They allow operators to set bale diameters steplessly from 1.00 m to 1.80 m to suit different crops, conditions and customer requirements.

|

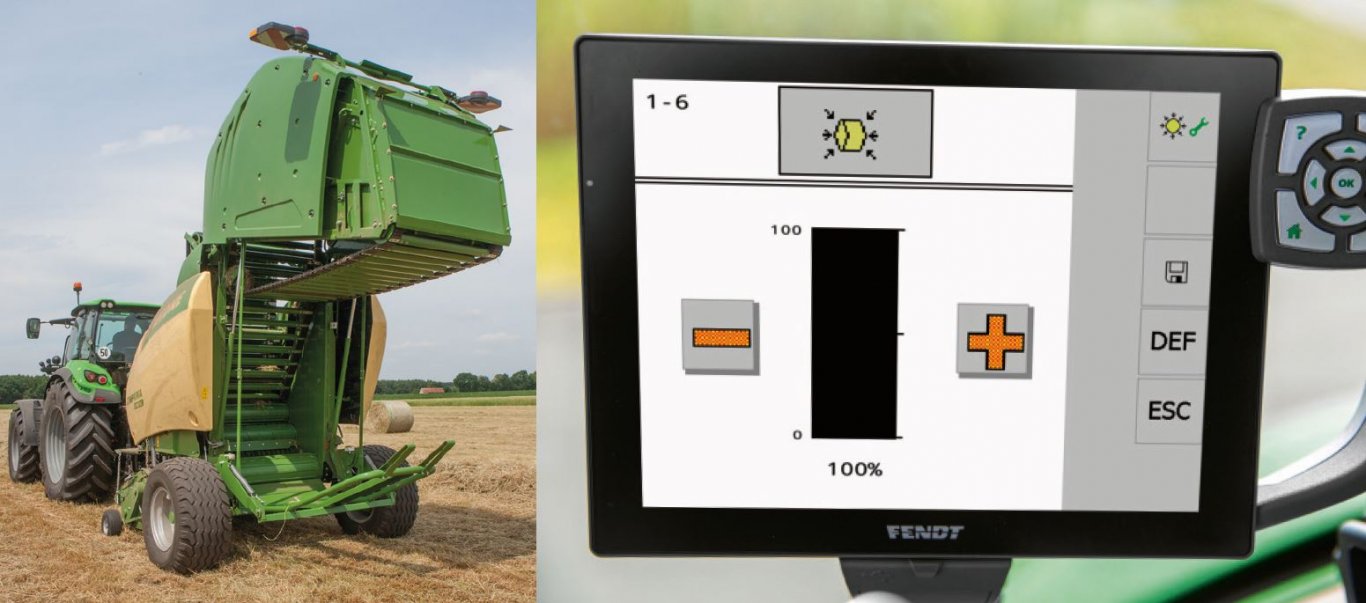

The Comprima V 150 XC and V 180 XC with variable bale chamber allow operators to enter the required bale diameter to the operator terminal from the comfort of the seat. The diameters can be set steplessly from 1.00 m to 1.50 m or 1.80 m. This way you are set to handle all crops and conditions. Smaller bale sizes are often preferred in grass silage whereas larger bales are more typical in hay and straw. Depending on the crop, the baling density in the core of the bale can be reduced, which is perfect for ventilating hay bales. 8 |

The Comprima CV 150 XC has a powerful double wrapper. The wrapping table forms a deep cradle and has large guide rollers on the sides to ensure the bale is consistently rolled during the wrapping process even when the conditions are more than difficult. The Comprima CV 150 XC table can also be used for unloading the bales in pairs when no wrapping takes place. |

The variable bale chamber on the Comprima V and CV models produces steplessly adjustable bale diameters of 1.00 m to 1.50 m or 1.80m. The actual bale size and the baling pressure are adjusted on the operator terminal. This way, you can adjust the density easily and conveniently to the conditions at hand. |

Once the bale is wrapped in the net, the tailgate of the baler opens. At the same time, the wrapping table inclines backwards, unloading the second already film-wrapped bale on the ground via a rubber rack. Now, the front bale is pushed from the transfer table onto the wrapping table by sturdy conveyor bars guided by chains on the right and left sides. As the baler resumes baling, the wrapper starts the wrapping process. |

The variable bale chamber is made up of two slat and belt conveyors. These form the bale as it grows to its preset diameter. Combined with springs and hydraulic cylinders, the double rocker in front and the tensioning arm in the rear generate a baling pressure which increases progressively as the bale diameter is growing. This technology produces an exceptionally high density. |

The Comprima wrapper wraps the bales fast and reliably – even in difficult conditions and in sloping fields.

|

The table on the Comprima wrapper forms a deep cradle and has big bobbins on either side that fix the faces of the bale as it is being rolled – an ideal setup for dependable operation in sloping fields. |

The wrapper takes 75 cm and 50 cm wide film material. The individual film width is set very easily and the number of wraps (4, 6, 8 or 10) is selected on the operating terminal. No matter which film width you choose, the layers overlap generously. Due to touchless sensors, the integrated film tear detection is particularly reliable. |

There are two large storage compartments on either side of the machine which store up 10 spare film rolls, protected from moisture and dust. Optionally, they can be equipped with powerful LED lighting. The film roll holders roll holders fold down for convenient removal and refills. |

The bale cloth is standard specification and protects the film from damage as the bale is placed on the ground. The optional bale turner gently tips the bales on their front. It does not need to be removed it is not required: simply fold it away close to the wrapping table. |

If not used for wrapping, the table can be used for depositing the bales in pairs, which leads to great time savings in clearing the field. |

Designed for premium bale productivity and density, the Comprima also convinces by its uncluttered design and exemplary accessibility. These features make it particularly easy to service. Grease banks and the automatic |

The large diameter of the gearwheels ensures particularly gentle deflection of the drive chain. This in combination with the automatic chain tensioner leads to a significant reduction of wear and thus to time and cost savings. |

A central chain lubrication system with eccentric pump and large reservoir (7 l) reduce the time that is required for service and maintenance. It further enhances the functional safety and economic efficiency of the Comprima. The desired oil feed rate is set at the pump. |

All grease points are grouped into easy-access grease banks, saving time and increasing the operator comfort. |

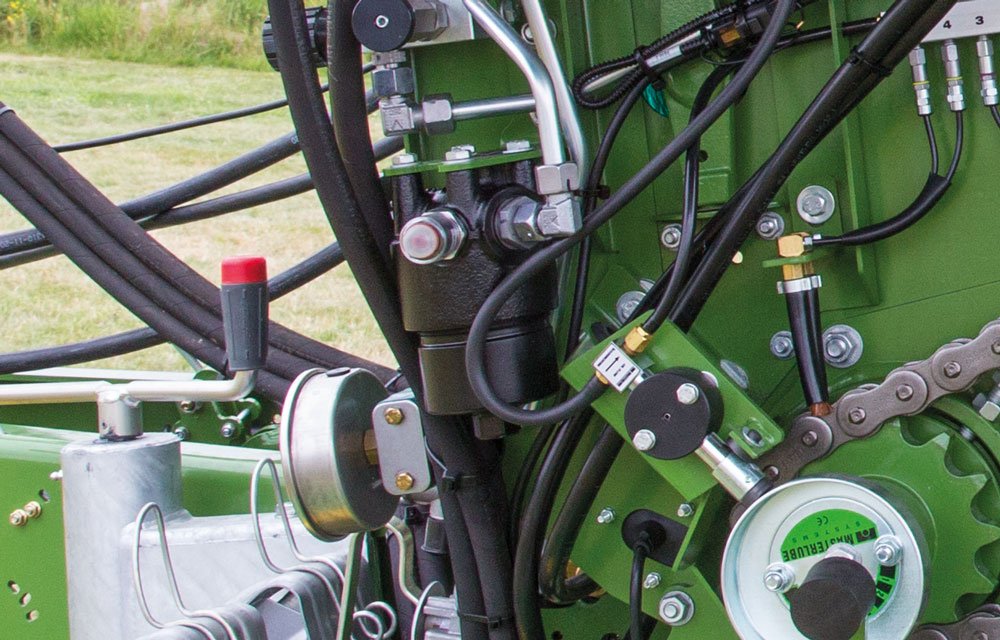

For utmost reliability, the hydraulic system on Comprima V, CF and CV is protected by an oil filter with a clogging indicator. |

KRONE offers a choice of four different terminals that cater for different applications and needs, making the Comprima round balers easier to use and notching up the work rate. All this makes the baler fun to use.

|

The CCI 800 and CCI 1200 operator terminals are equipped with large 8" or 12" colour displays with touch function which display the machine controls and camera footage side by side on the same screen. Both terminals are ISOBUS compatible and therefore universal terminals that are ready for use on other machines as well. |

If the operating terminal on the tractor is ISOBUS compatible, it can log into the on-board electronic system of Comprima. This eliminates an extra terminal which in turn improves all round visibility. |

The blades are protected from damage by spring locks. In case of contact with a foreign object, each blade individually ducks down and automatically returns to its initial position later on. a system that results in dependable and high-quality cuts.

The blades are protected from damage by spring locks. In case of contact with a foreign object, each blade individually ducks down and automatically returns to its initial position later on. a system that results in dependable and high-quality cuts.