- Monday 8:00 am - 5:30 pm

- Tuesday 8:00 am - 5:30 pm

- Wednesday 8:00 am - 5:30 pm

- Thursday 8:00 am - 5:30 pm

- Friday 8:00 am - 5:30 pm

- Saturday 8:00 am - 3:00 pm

- Sunday Closed

Sunflower 1710HD HEAVY-DUTY OFFSET DISC HARROWS

WORKING WIDTHS FROM 11’ 9” TO 17’ 6”

Some jobs simply take more. The Sunflower 1710HD Series Offset Disc Harrows are built tough to withstand the rigors of the construction, mining and forest industries.

Robust 6” x 12” x 3/8” tubular steel frames and 36” diameter disc blades combine to produce working weights in excess of 900 pounds per blade. Large diameter notched disc blades with 2-3/4” gang shafts and 18” blade spacings creates a low bearing to blade ratio, eliminating expensive down time on the job site.

The Sunflower 1700HD Series is heavy and heavy-duty to make easy work of the toughest construction and agricultural conditions.

|

1710HD HEAVY-DUTY OFFSET DISC HARROWS FEATURES

-

Self-leveling all-welded frame

-

6’ x 12” x 3/8” tubular frame

-

18” blade spacing

-

36” x .472” notched blades

-

2-3/4” ang shafts

-

10-Bolt hubs

-

385/65R 22.50 (used) tires

-

Two Models: 11’ 9” & 17’ 6”

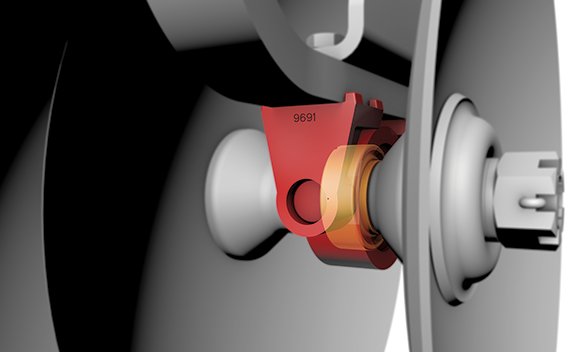

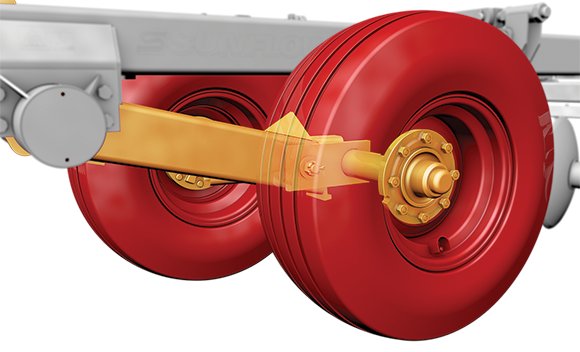

TRUNNION MOUNTED BEARINGSSunflower’s trunnion bearings provide positive alignment and eliminate side-loading of the bearings along with the housing to ensure positive lubrication. The trunnion bearing features triple-lip seals that cannot be damaged by daily greasing. Metal washers protect the seals from being damaged by stocks or material wrapping around the gang shaft.

Featured on all except 1700 and 1800 series. |

C-FLEX™ BEARING ARMSThe C-Flex bearing arms absorb disc gang shock created by stumps, rocks and normal discing, which extends the bearing, spool and disc blade life. They also clear residue better than conventional rigid standards and allow for easy maintenance of the disc gang assembly. Unlike on competitive machines, the scraper bars are mounted to the back of the C-Flex arms, which allow the scrapers to react with the gang and not come into contact with the spools or blades. Featured on all except 1700 and 1800 series. |

SELF-LEVELING HITCHLevel the disc frame from front to rear with Sunflower’s self-leveling hitch. This positive adjustment maintains a pre-selected setting regardless of the tillage depth. It features heavy-duty compression springs on each side of the pivot to cushion both front and rear gangs, important when crossing ditches or rough terrain. Some disc models offer optional hydraulic adjustment. Featured on all series. |

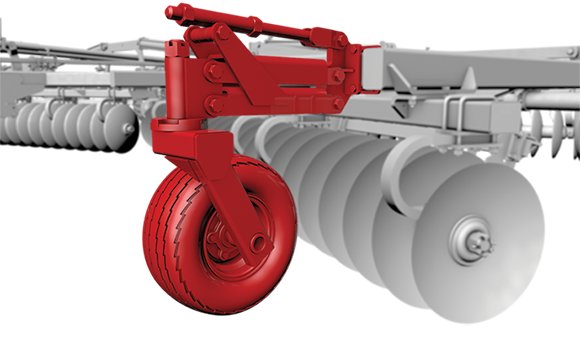

FRONT-MOUNTED GAUGE WHEELSAll flexible Sunflower discs have front-mounted gauge wheels. This important feature prevents the front gangs of the wing frame from gouging, buckling or cutting deeper than the other gangs, promoting a level, ridge- or furrow-free field. The heavy-duty gauge wheels feature a five-bolt hub and 8x10 ply tire.

Featured on all winged units except 1700 and 1800 series. |

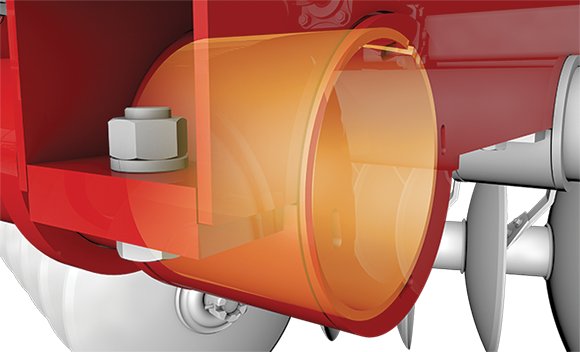

MAINTENANCE-FREE LIFT SYSTEMSSunflower discs are equipped with maintenance-free lift systems that pivot on space-age UHMW polymer sleeves, eliminating greasing.

Featured on all except 1700 and 1800 series. |

MAINTENANCE-FREE WING HINGESMaintenance-free wing hinges that utilize the same UHMW technology as the lift systems are used on most models. Featured on all except 1300, 1700 and 1800 series. |

SPRING-CUSHION GANG ASSEMBLYThe entire gang assembly pivots upward when an obstruction is encountered. The heavy coil springs compress, allowing the gang assembly to pass over the obstruction, then expand to return the gangs to their working position. Optional on 1700 & 1800 series. The rigid gang assembly is standard equipment on the 1700 and 1800 series. |

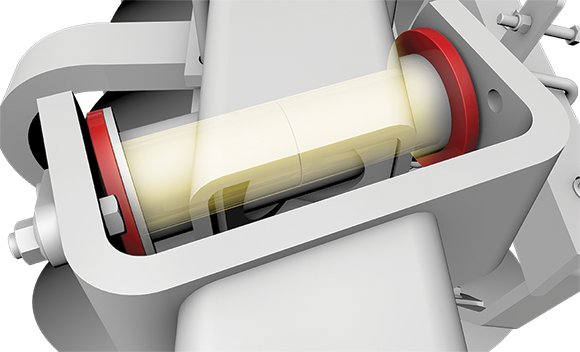

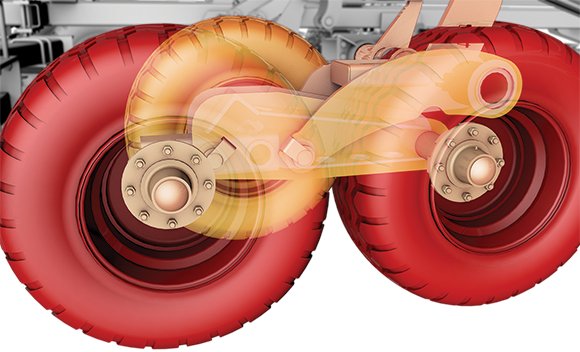

WALKING TANDEMSThe walking beam pivot assemblies consist of two tapered roller bearings with triple-lipped seals. For ease of service and strength, the wheel spindles of all configurations—dual, tandem or triples—slip into the spindle tube, which is welded into the walking beam.

Featured on all except 1212 series. |

WALKING TRIPLE TANDEMSCenter-section walking triple tandems have 50% more weight-carrying capacity than conventional walking tandems. Featured on 1550 series. |